If you're trying to replace your edger blade for the first time then you'll want to know if its nut is reverse-threaded or not. We have researched the answer to this question and here's what we found.

Generally, an edger blade's nut is reverse-threaded. You turn the nut to the left to tighten it and to the right to loosen it.

When loosening any nut, you need to make sure that it goes in the right way. You don't want to destroy your lawn edger by overtightening the nut instead of loosening it. Keep reading as we talk about how you replace your edger blade and how to do it correctly. We'll also answer some relevant questions related to the topic that you may find useful.

When Should You Replace Your Edger Blade?

Edger blades are important tools for landscapers. They allow you to cut around corners and edges and trim around extra, unsightly growth. But when should you replace your edger blade?

To find out how long your edger blade should last, you should be aware of how often you use it. The more you use it, the faster it will wear.

In fact, you can easily tell how much your edger blade is worn out by looking at the way it cuts the grass. Typically, an edger blade should last for the entire season without replacement.

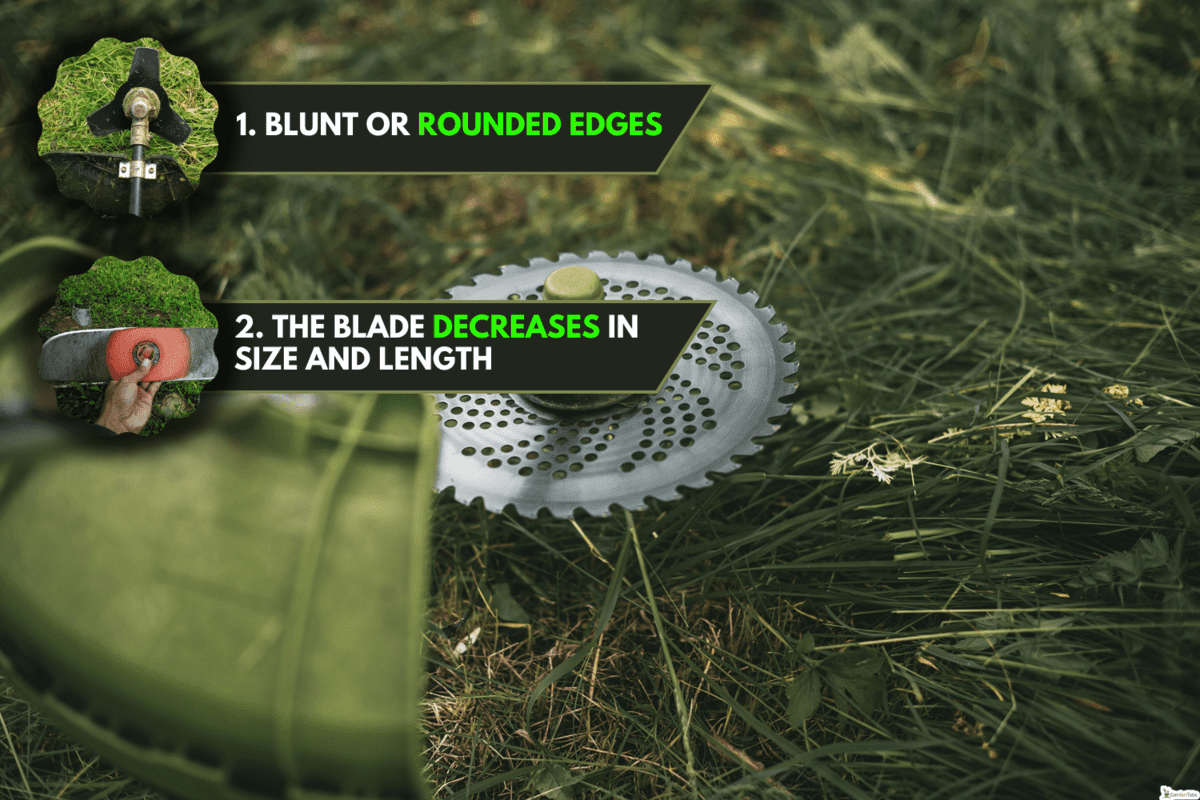

Here are a couple of signs that indicate it's time to replace your edger blade:

1. Blunt or rounded edges

The cutting edges on edger blades are quite vulnerable to wear, which can make the blades blunt or rounded. Bluntness in an edger blade makes it less effective at cutting. A blunt blade will unevenly cut edges and make it difficult to achieve a uniform look.

2. The blade decreases in size and length

As the blades get worn, the cutting edge gets smaller and shorter, causing the edger blade to decrease in size. One of the main reasons why your edger blade is becoming smaller over time is that it could be caused by the friction of the blades against the pavement.

How To Replace Edger Blade

1. Clamp and hold the blade on a vise.

2. Look for a tiny hole at the back of the blade.

3. Lock the transmission so the blade won't turn when you try to loosen the nut. To do this, insert a piece of metal or any suitable material or tool that you can find to fit into the tiny hole.

4. Use a 3/4-inch socket to loosen the nut. An impact wrench will make the job easier but you can also do it manually as long as you have to use a breaker bar to aid you in leveraging the nut.

5. Once you've loosened the nut, pull it out along with the washer and then remove the blade.

6. Install the new blade. Tighten the nut to ensure the blade is snug in place.

How To Edge a Lawn

Edging a lawn is a simple way to beautify your lawn without spending a fortune. It can create a seamless transition from your lawn to your flowerbeds, borders, walkways, and driveways.

Most people assume that edging should go around the entire perimeter of their lawn. But you don't need to do that. Edging depends on what you want to achieve with your lawn, so you need to figure out what you want to do.

Here's the best way to do it:

1. Identify the edges where you want to trim. Once you've identified them, determine the depth and set the blade to cut at that depth.

2. Choose your preferred starting point and run the edger along the edges and corners of your lawn, making sure to keep the edger in a straight line.

3. Continue edging until you have finished the entire lawn perimeter. The key to having a well-manicured lawn is keeping the lawn edge at an even height. That means you need to keep it straight and level across the entire lawn surface.

Can You Flip an Edger Blade and Use The Other Side of It?

It’s not uncommon for an edger blade to fail after a few seasons of use. In most cases, the problem is simply a result of the blade wearing down. If your edger blade is worn down, you can use the other side to maximize the life of your edger.

It can save you some money and time because you won't need to replace it as soon as you would've had to otherwise.

Do Edger Blades Come Sharpened?

The cutting edge of an edger blade is not the same as that of a lawn mower blade. Unlike a lawn mower's blade which has been ground to a very fine edge, an edger blade has a square edge.

This means that it's safe to handle and you won't get cut or injured while replacing it. The square edge of an edger blade is enough to cut through grass or other vegetation.

Check out these edger blades on Amazon.

Should I Mow or Edge First?

Most homeowners prefer to mow their lawns first because it makes the grass shorter and easier to manage. Mow the lawn at an even pace and make sure you don't leave a section of the lawn untouched.

The grass in your lawn grows at different speeds. By mowing the grass first, you allow the slower-growing grass to catch up with the faster-growing grass. This gives your lawn a uniform look.

If you've been edging the lawn for years, you probably know it takes a long time to do so with tall grass. A shorter grass to work on will also mean less strain on your edger blade.

Should I Edge My Lawn Every Time I Mow It?

It's important to ensure the grass in your lawn is kept neat and tidy. It helps keep your home looking good and is a great way to add curb appeal. A clean-cut lawn will look attractive, neat, and healthy.

On the other hand, a patchy lawn has unsightly, uneven patches of grass. It can be detrimental to the overall appearance of your property. To make your lawn look its best, you should edge the grass every time you mow it.

It's like getting a haircut. You don't expect the barber to cut selected areas of your hair without cutting the rest. You have to trim the edges of your head to get a good shape and uniform growth.

How Often Should I Mow My Lawn?

In general, it's best to mow every week or two, though there are exceptions to this rule. The frequency of mowing your lawn will depend on the length of time it takes for your lawn to grow back.

The longer you let it grow, the thicker and tougher it gets, making it less susceptible to damage from the lawn mower and the more strain the grass will put on the mower. Lawns that have not been mowed regularly can become very long and tangled.

How Deep Should I Set the Edger Blade When Edging?

Before using a lawn edger, make sure to set it at the correct depth. The depth should be set to no more than 2 inches below the level of the soil. However, the amount of grass you want to maintain should determine the depth, so you have plenty of room to adjust this.

For example, if you only want to edge a few inches off your lawn, you can set the depth to your desired height and edge the grass to that length.

But if you're looking to edge the grass completely, then you'll have to dig down to the soil that's located 6 to 8 inches below the surface. You will have to set the edging at a depth that will reach the root zone of the grass.

What is the Ideal Angle When Edging a Lawn?

The ideal angle for edging your grass should be approximately 20 to 40 degrees. This angle should allow your grass to grow naturally but still maintain its shape.

Can I Use My Edger to Dig a Trench?

An edger can be used for digging trenches in your yard but the size of the edger will limit its usefulness. Digging a deep lawn or garden trench should only be done with a rototiller. A rototiller is a machine that uses a rotating blade to turn over the soil.

It's important to know that you cannot use the edger to dig deeper than one foot or more than what the manufacturer recommends.

This is because it will not be sturdy enough to handle the weight of the earth. This will cause the edger blade to wear out faster and in some cases, break, especially if it will hit a rock.

Check out this rototiller on Amazon.

What are Edger Blades Made From?

Edger blades are mostly made from high-quality carbon steel. High-carbon steel is a good material for lawn and gardening applications. It is less malleable than low-carbon steel, which means it won’t bend or flex.

A common way of measuring the quality of a metal is through its yield strength. Yield strength is the point at which a metal can sustain a load without breaking.

An edger blade has more than sufficient yield strength to slice through grass and withstand friction against the pavement.

In Closing

There are numerous cases when machines break because the nut was assumed to be a standard nut. As a result, the nut was overtightened by the impact wrench and the thread was stripped off.

The edger blade has a reverse thread so that you tighten it when you turn the blade counterclockwise and loosen it when you turn the nut clockwise. Knowing the thread pattern of a certain nut is important because it determines which direction the thread goes in.

You might also like:

My Echo Edger Won't Start; Why? What To Do?

Can You Use An Edger Along A Fence [Without Causing Damage]?