Power takeoff, or PTO, as most people call it, is one crucial component of a tractor or riding lawnmower. It is responsible for engaging the mower blades. And since it is vital in a mower, knowing what will happen if it goes bad is also essential. Good thing that after our thorough research, we have determined the answer.

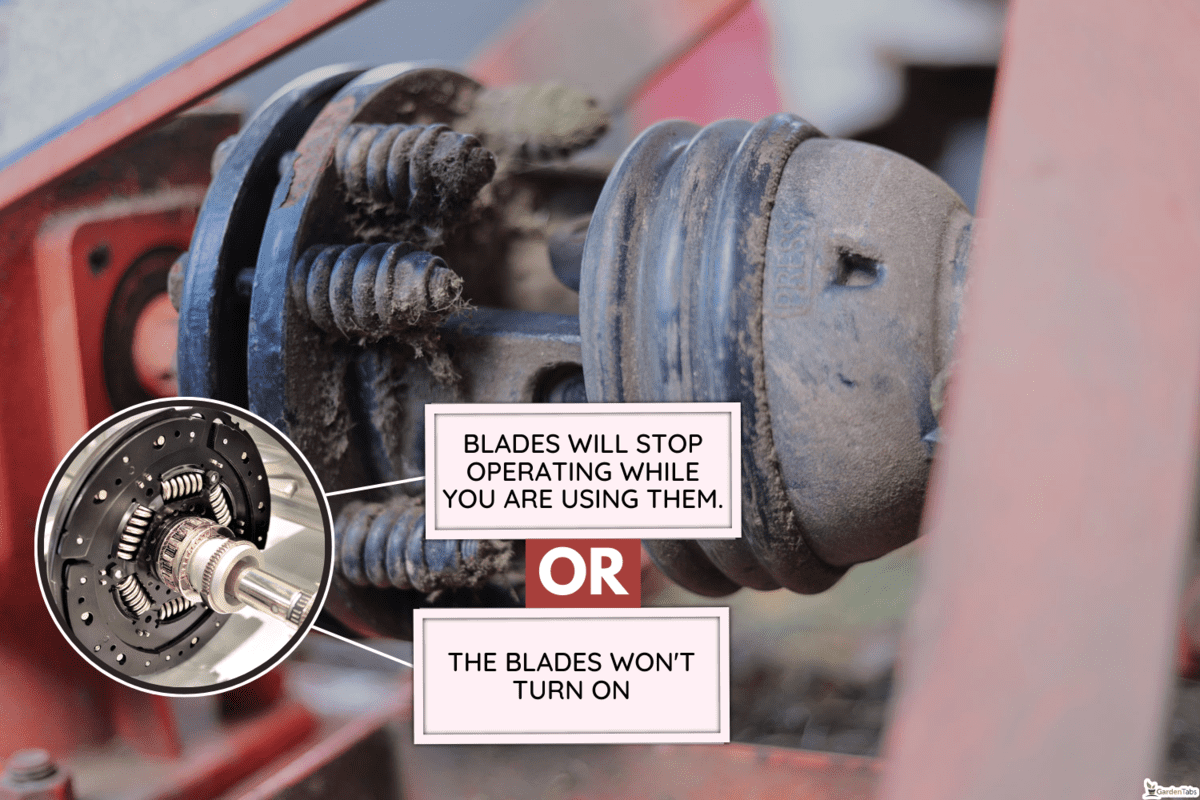

If the PTO clutch goes bad, expect the blades to stop operating while you are using them, or worse, the blades won't turn on at all. So, if you notice something bad in your mower's PTO clutch, it would be best to inspect and repair it immediately to avoid further damage and continue the mowing process.

This article will let you know the different symptoms of a bad PTO clutch and how to repair it. So, we highly suggest you keep reading. Doing so will also help you learn how to inspect a bad or faulty PTO clutch properly. And without further ado, let's delve into the details!

What Will Happen If The PTO Clutch Of A Mower Goes Bad?

As you use your rider mower, the PTO clutch connection could weaken over time. And as mentioned, your mower's blades will either turn off while in operation or refuse to start if the PTO clutch fails. So, if you are to mow your lawn, it is advisable to check the connection first before using the machine.

Issues with the PTO clutch, engine, and knob usually result from a breakdown somewhere on the electricity line connecting the three. You can look at the different nodes for signs of wear and tear or rupture by peeling back the covers.

How Can You Tell If The PTO Clutch Is Bad?

There are some symptoms that you can notice in a bad PTO clutch, and they are the following:

You Can't Start It Easily

Slow engagement is a common sign of a faulty PTO clutch. Initial activation of the blades can take a few seconds. And after a time of operation, the temperature will rise.

It Will Produce Unwanted Sound

A faulty PTO clutch will produce unnecessary or unwanted sound as it engages or disengages.

There is an issue with the PTO clutch if the car makes unwanted noise when the transmission is in neutral, but the noise disappears when you depress the clutch pedal. One potential source of the noise is a failed input shaft bearing. The noises you can hear are grinding, whirring, and chirping.

Noise is a good indicator of whether or not the clutch needs servicing. To do so, make sure it's not engaging and then cycle the power on and off several times. If the PTO gradually slows or stops without making a withdrawal sound, the power takeoff clutch is likely galling together to heat, or there is a clogged slip ring.

The Engine Won't Start

You'll immediately know if the PTO clutch solenoid is faulty if the blades won't turn. Furthermore, if the switch also has issues, expect no power to reach the engine of your rider mower.

What To Do To Repair Specific PTO Clutch Issues Immediately?

In every PTO clutch issue, know that you can't solve it with only one approach or repair. Also, there are instances when you might need to change the PTO clutch to a new one. However, keep in mind that regularly checking and adjusting them can prevent the occurrence of problems. To give you some idea, check the details below:

How To Inspect A PTO Clutch?

If the PTO clutch drifts too much, gets stuck, or the power goes out, expect to have difficulty operating the mower or tractor. In order to ensure that this PTO clutch engages and disengages at the correct times, you should conduct several inspections.

1. Get The Floor Jack To Lift The Mower

The first thing you should do is lift the riding mower. Raise the mower off the ground by using four jack stands.

Locate the two jack stands beneath the front and rear frames. Jack up the machine just enough so that you can see beneath the mower deck and get a look at the PTO clutch drive set-up. If you have difficulty locating the battery, refer to the owner's manual for the riding mower make/model.

Some riding seats tilt up for battery access.

Click here to check out this Pro-Lift floor jack on Amazon.

2. Set The Correct Battery Modification

In this step, you will need to connect the positive lead of a voltmeter on the red, positive terminal on the mower's battery. Additionally, you should join the negative voltmeter to lead to a reliable power supply in the engine. Keep in mind that you should consider the volts.

Charging the battery is advisable if the voltage reading is 12.5 or less. Moreover, know that the PTO clutch won't start and engage if there is not enough voltage present.

3. Find The Fuse

Underneath the deck, you will find the PTO clutch system and the fuse that protects it from overloading the electrical circuit that connects the lever button. You should check out the fuse filament by unscrewing the cap cables.

If the fuse filament has burned out or the fuse itself has turned black, changing it with a new fuse is highly advisable. Furthermore, one crucial thing you should consider here is to ensure to use of a fuse of the exact amperage capacity.

4. Let The Engine Warm Up & Inspect the Blade for Smooth Rotations

In this step, you will need to switch on the engine. Let it run while you activate the PTO clutch by pulling the lever.

Look under the mower deck -keeping your distance -to see if the blades are spinning. A screeching or squealing sound is a bad sign. Turn off the engine if you hear unusual noises like these. Wait for the blades to stop rotating, and then:

- Using a socket, unplug the battery's negative line.

- Remove any dirt, leaves, twigs, or other debris from the mower deck

- Check the drive belt tension; replace if you discover any worn or damaged areas.

- Plug in the negative battery cable.

- Restart the engine. Engage the PTO, and then release the button. Cycle the power repeatedly.

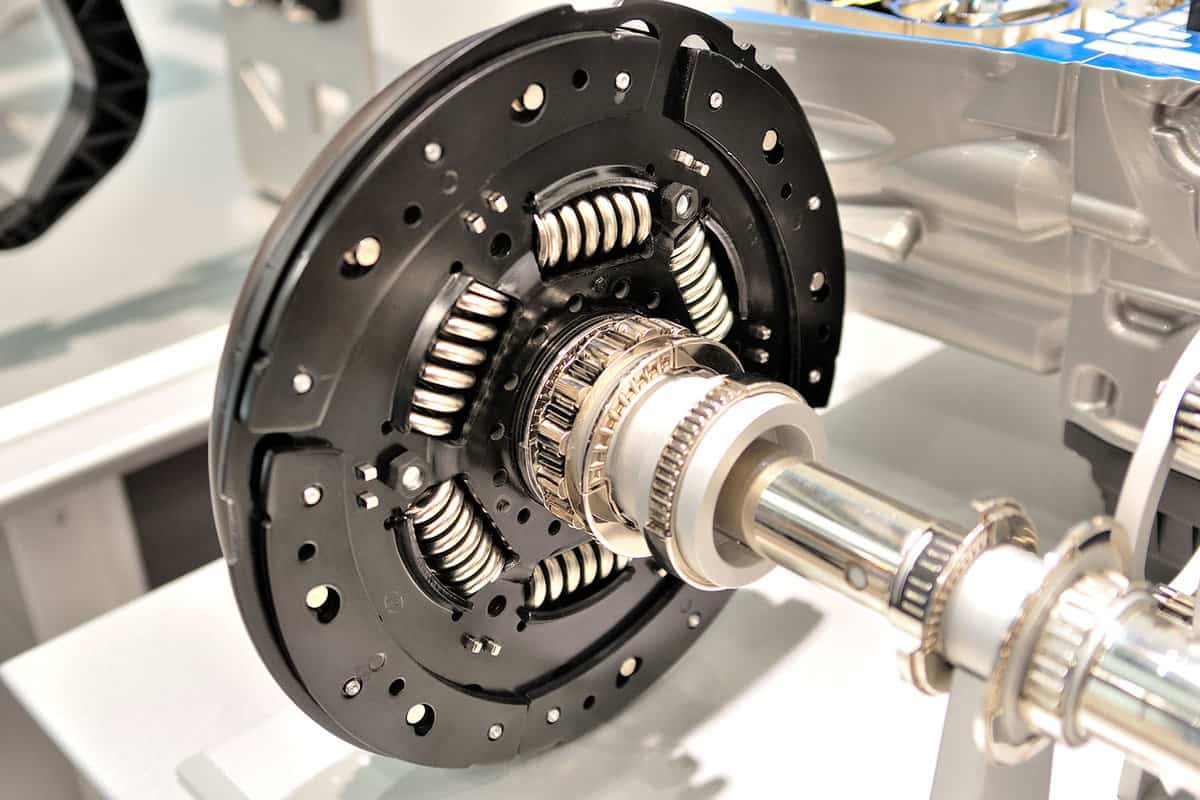

You can quickly notice a galled clutch and plates or a jammed slip ring if there is an absence of a detachment sound or the PTO pulley's failure to stop or slow down. Removing the clutch and examining its inner workings would be best.

Disconnect The Main Supply Cable From The PTO Clutch

Unplug the primary power cable from the PTO clutch, which you can find on the side of the clutch.

It is advisable to face the wire jack inward and move back from the surface as far as possible. Afterward, prepare the negative alligator lead of a test light and carefully attach it to a ground source. But before doing it, ensure the engine is off while the battery is still linked.

Lastly, link the test light's probe to the PTO clutch's red wire by inserting it into the connector's internal hole.

5. Check The Test Light For Success

Check the test light's bulb for illumination after activating the PTO clutch lever. And if the lever switch position does not light up, the activation control probably failed. You should double-check the voltage level and the in-line fuse before assuming the lever switch is at fault.

Connect The Positive Terminal To The Red Power Wire

In this step, you will need a wire cutter to sever a wire with enough length to connect the PTO's red power wire to the battery's positive terminal. Don't forget to plug in the battery cords!

Additionally, you should ensure to link the jumper wire to the positive battery's terminal. On the other hand, you must connect the battery's negative end to the PTO jack's red positive wire.

6. Listen for Clicking

Notice if there is a receptive click. It's highly probable that the armature and propeller in the PTO clutch assembly's electrical circuit are at fault if you cannot detect any noise.

Wrapping It All Up!

PTO clutches are crucial components of compact tractors, as they turn the mower blades. If you want the best results, you'll have to perform routine upkeep. Doing so will also prevent the blades from turning off while in operation or not turning on at all.

You have finally made it to the end! We hope you find this post helpful. Please feel free to comment if you still have additional concerns or questions. And if you wish to continue reading, you can check these other posts!

How To Use A Tiller To Remove Weeds [Step By Step Guide]

My John Deere Mower Makes A Loud Noise When Turning – Why? What To Do?