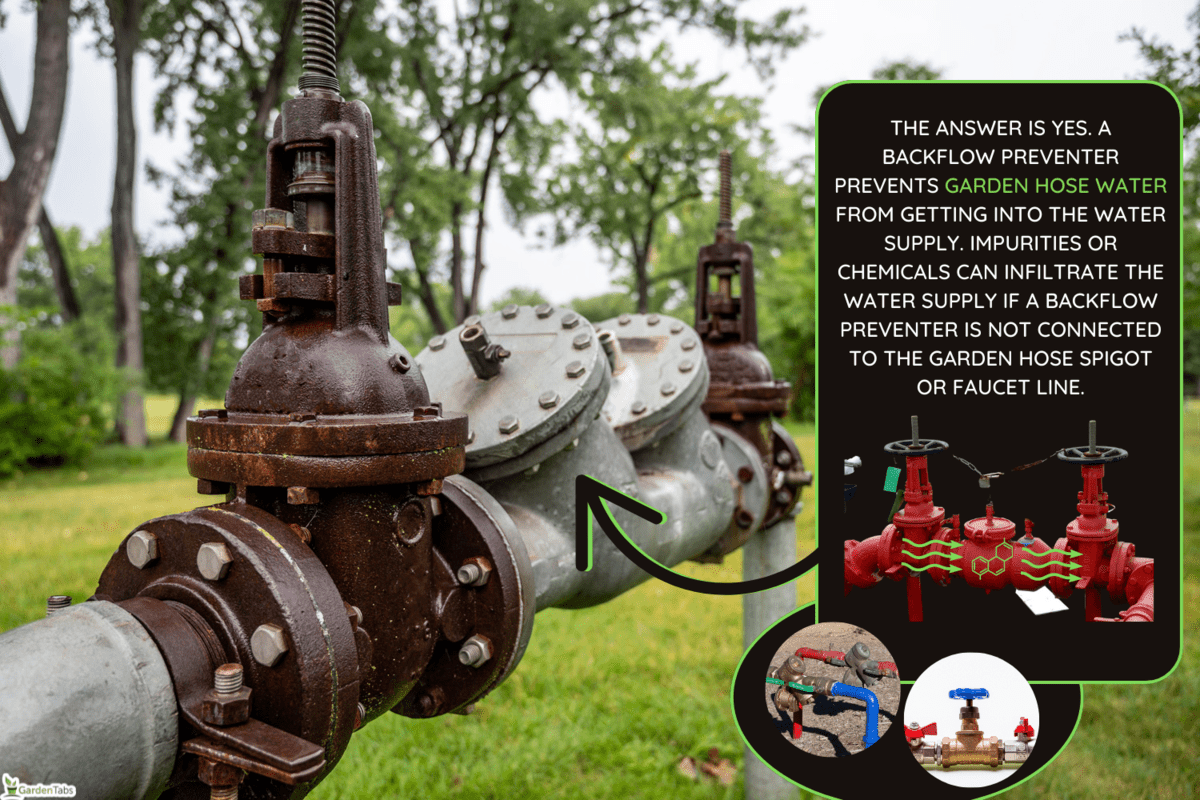

Backflow preventers are the device you typically find on outdoor spigots and are at the end of hose spigots. However, is a backflow preventer necessary for your hose garden? We did the necessary research to deliver the facts to you. Here is what we found out.

The answer is yes. A backflow preventer prevents garden hose water from getting into the water supply. Impurities or chemicals can infiltrate the water supply if a backflow preventer is not connected to the garden hose spigot or faucet line.

The typical garden hose check valve is made of brass and is only marginally bigger than an outdoor garden hose. There are attachment terminals on both the male and female sides. Only a few inches and a few ounces total measure the length and weight of this entire unit. Read on as we go into great detail about it.

How Does a Backflow Preventer Work

Water from those building systems, such as plumbing leaks or water management, can backflow further into the main municipal supply system. This is because of the pressure fluctuations in water pipelines.

In such situations, contaminants, such as dangerous chemicals, human waste, and many others, are seriously concerning. It may contaminate the water supply of the general public.

A backflow preventer has several tremendous advantages which could help homeowners like you. Installing a backflow preventer is an excellent foolproof technique to maintain good health.

This will ensure as well that household drinking water remains contaminant-free. The plumbing system can be protected well from impurities by installing a backflow preventer, extending the pipes' life.

With such a backflow preventer, homeowners can rest assured that they won't need to be concerned about contaminated drinking water or expensive repairs.

Watch the video below for more understanding of how the backflow preventer works.

Backflow Prevention Types

Backflow preventers come in a variety of designs, each having unique uses and functions. A plumber may advise the best type for your home and what the municipality requires. Here, we'll discuss the many kinds of backflow preventers and how they operate.

Air Vacuum Breaker Assembly (AVB)

An air inlet valve, a port, and a check seat are features of the non-pressure type vacuum breaker known as an AVB. Due to water entry into the body, the air inlet valve closes the air inlet port.

The air intake valve collapses and acts as a check valve to prevent reverse siphonage whenever the water flow is stopped. As it does so, the air input port opens, allowing air to enter and fill the vacuum.

However, there must not be any shutoff valves or impediments downstream. The assembly may include a shutoff valve that is directly upstream. Upwards of 12 hours in any period of 24 hours cannot be spent under operating strain on the assembly.

You may watch the video below to understand this kind of backflow preventer.

Pressure Vacuum Breaker Assembly (PVB)

This particular component includes a separately operated and independently operated check valve with an internal actuating the discharge-side filled air inlet valve on the check valve's side.

This assembly must be outfitted with appropriately positioned resistant testing cocks seated and robust seated cutoff valves that close and tightly connected at the assembly's ends.

Find this pressure vacuum breaker on Amazon.

Air Gap

This third kind of backflow preventer is a barrier dividing the free-flowing discharging end of a drinkable water supply pipeline from an open or low-pressure receiving vessel.

This must not be applied in a risky situation. An "allowed air gap" should have a width at least twice that of the supply pipe if calculated vertically above the overflow lip of the receiving vessel.

Watch the video below for a thorough understanding of how the air gap works.

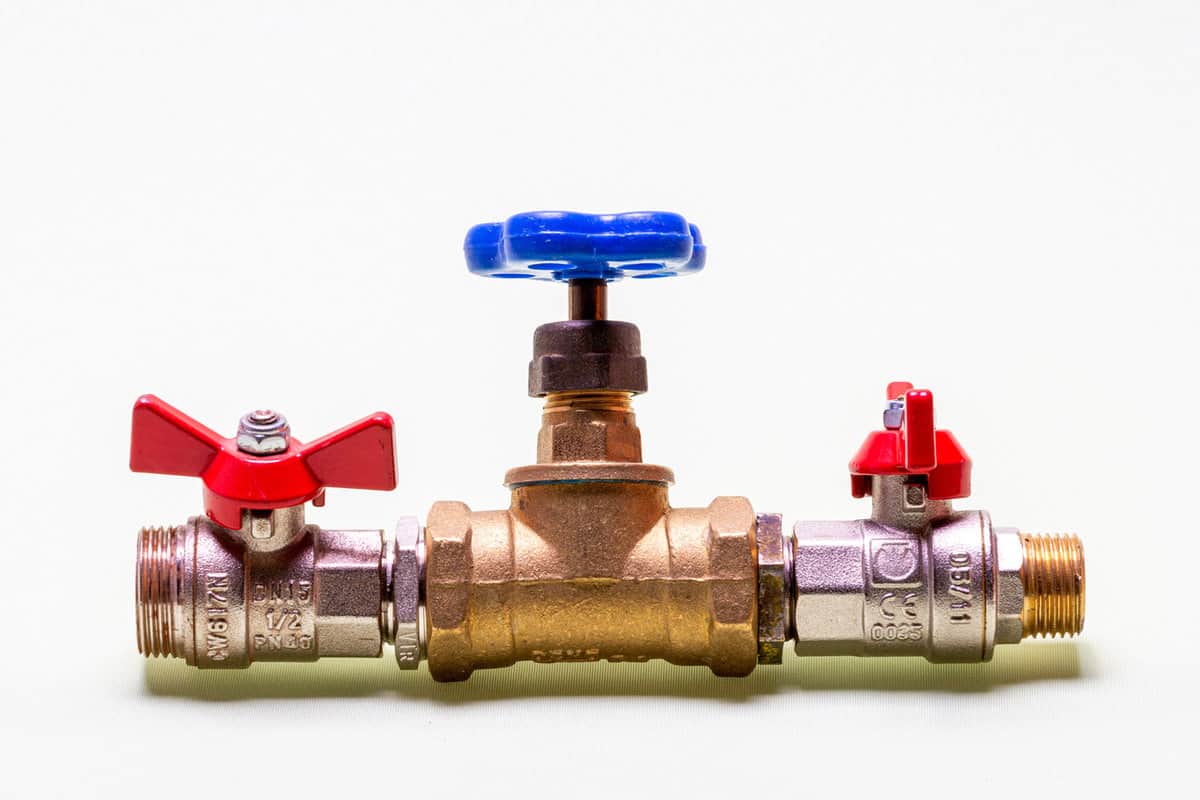

Double Check Valve Assembly (DCA)

This assembly comprises two independently operating, authorized check valves and shutdown valves that are firmly shutting and linked at installed correctly situated robust test cocks seated at every end of the unit.

Reduced Pressure Zone Device

The most intricate and expensive backflow preventer is a reduced pressure zone device, which is also occasionally referred to as a reduced pressure principle assembly. The most secure and dependable backflow prevention device available is this particular type when it is operating correctly.

An outlet shutoff valve, four test cocks, two independently working spring-loaded check valves, a pressure differential relief valve, and an intake shutoff valve make up a reduced pressure zone device.

Hose Bib Vacuum Breaker

An outdoor faucet that has a hose connection often uses a hose bib vacuum breaker. The single spring-loaded check valve on such a threaded device, which may be fastened onto the spigot, stops backflow.

Non-potable water cannot be siphoned through the hose's end by permitting water to flow only one way. Also, with opening and closing the valve in response to water pressure.

You may watch this video on how the hose bib vacuum breaker works.

Check out this hose bib vacuum breaker on Amazon.

Backflow Preventer And Check Valves—Are They The Same

Check valves, and backflow preventers are essential plumbing safety precautions that share the same operating principles yet accomplish significantly specific aims. The main distinction between backflow preventers and check valves is where they are used.

A check valve is employed in low-risk settings to limit the reverse flow of water yet lacks the same fail-safe elements as a backflow preventer, which is utilized in high-risk circumstances and therefore is wholly created to safeguard potable water. Let's begin by discussing the primary causes of backflow.

Both backpressure and back siphoning could be the reason. Backpressure happens whenever the source piping's pressure is greater compared to the downstream piping. This could be caused by pumping, temperature contraction, or high head pressure, among other things.

Negative pressure inside the supply piping causes back siphoning to happen. The stream of a downstream pipe may change course and revert toward the source line as just a result of a water main break or higher-than-normal draw rates, such as those produced by a fire hydrant outflow.

Because downstream chemically processed water, like that found inside an HVAC cooling water loop or a chemical sprayer connected to a garden hose, can contaminate the public water supply in either scenario, the proper safeguards must be in place.

In the event of backflow, contaminants, such as chemicals, bacteria, and sediments, may be sucked into the capital's water system pipe for domestic use before being redirected to a consumer for preparing food, drinking, or other potentially dangerous uses.

How Is A Garden Hose Backflow Preventer Installed

To create a tidy space to work, begin by separating your garden hose from the spigot, then dry the surface with such a cloth. A replacement valve should then be screwed into the external faucet. Ensure that you rotate it just enough to ensure that the gasket is watertight but be careful not to twist it excessively, or the device may shatter. Avoid causing irreversible damage. Double-check the alignment if it is difficult to attach.

Do Backflow Preventer Devices Need To Be Used

The majority of residential properties don't need backflow prevention. But if your house has an irrigation system, your town hall might insist for you have this system set up.

Many local governments around the country mandate annual testing of backflow preventer devices for business plumbing systems. Annual testing is necessary for regions wherein household preventer devices are mandated.

A licensed plumber who has worked with preventer devices before should perform the test. Every preventer is put through its paces by the plumber to ensure proper operation.

Many plumbing businesses that provide this service also file documentation with the city to maintain your house or place of business in compliance. If such a device malfunction while being tested, the plumber fixes it. In some circumstances, replacement is necessary when fixes are ineffective.

Wrap Up

You have now read the entire article and have both the answer to your query and an explanation. For the sake of everyone's safety in the home, a backflow preventer is required for your hose garden. We also discussed different backflow preventer types and other relevant issues you might encounter.

Here are other articles that you may want to read:

Tilling: The Ultimate Guide For Your Home Garden Success

How Do You Protect a Terrace, Patio, or Roof Garden From Rain?